| C | Si | Mn | P | S | Cr | Ni | Mo | V |

|---|---|---|---|---|---|---|---|---|

| 0.50-0.60 | 0.10-0.40 | 0.65-0.95 | 0.03 | 0.03 | 1.00-1.20 | 1.50-1.80 | 0.45-0.55 | 0.07-0.12 |

DIN 1.2714 is highly recommendable for Close Die Forgings due to its characteristics of high wear-resistance, extra toughness , high hardness which is achieved with Cr-Ni-Mo-V high graded alloys. The equivalent grade DB6 / L6 / SKT4 normally used as a pre hardened condition. The standard hardness is 360 to 430 BHN. DIN 2714 is the upgraded version of DIN 2713 for better performance of dies. We supply Die blocks as the extra Forging Reduction & Upsetting with Double tempered to achieve the better Ultrasonic quality.

DIN 1.2714 is a tool steel grade that comes under the DIN EN ISO 4957 standard. Due to its excellent combination of wear resistance, additional toughness, and high hardness which are attained using Cr-Ni-Mo-V high graded alloys, DB6 Steel is highly recommended for Close Die Forgings. Therefore, DB6 Steel is the material of choice in the automotive, aerospace, metalworking, and tool and die sectors. We provide die blocks as an additional forging reduction and upsetting step with double tempering to improve ultrasonic quality.

Virat Special Steels is the largest stockiest and supplier of DIN 2714 tool steel in flat, square and round bar. We provide steel in all sizes as your requirements. DIN 2714 die steel is available in flat, square and round shape. Consult our team who will assist you for DIN 2714 steel query.

The special Hot Work Pre hardened Steel with good toughness and high ware resistance. Die Steel is normally supply in hard, quenched & tempered and also in annealed condition in special case. Usually its working hardness is 360-430 BHN. This steel grade is the upgrade version of DB6 / DIN 2713 / AISI L6 for better performance.

| Tensile strength | 1000-1400 MPa |

| Yield Strength | 1045 MPa |

| Elongation | 15%-20% |

| Impact Toughness | 20 J/cm2-25 J/cm2 |

| Hardness | 50-55 HRC |

| Compressive Strength | 2500MPa |

| Modulus of elasticity | 205 GPa |

The exact values of these physical characteristics depend on the composition, heat treatment, and manufacturing procedures used to create DB6 steel, so take them with a grain of salt. For detailed details on the physical characteristics of a certain grade of DB6/DIN 2714/AISI L6 steel, it is always advised to refer to the manufacturer's datasheet or specifications.

| Coefficient of thermal expansionat °C | 20-100 | 20-200 | 20-300 | 20-400 | 20-500 | 20-600 |

| 10-6 m/(m*K) | 12.1 | 13.1 | 13.2 | 13.5 | 14.1 | 14.3 |

| Thermal Conductivity °C | 20 | 350 | 700 |

| W/(m*K) | 35.0 | 39.0 | 36.0 |

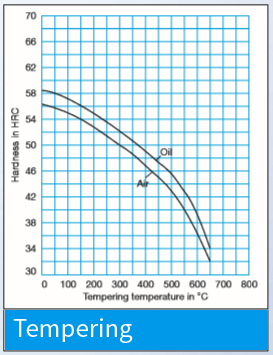

Different hardness according to different Tempering temperature conditions.

- Annealed condition - 255 BHN max

- Hardened and Tempered condition- 38 to 42 HRC

- Hardness variation from surface to core – 20 to 25 BHN

The machinability of tool steel DB6/ DIN 2714/ AISI L6 is very good & It rates 90% of the machinability of the W-group water hardening low alloy steels rated 100% as a baseline.

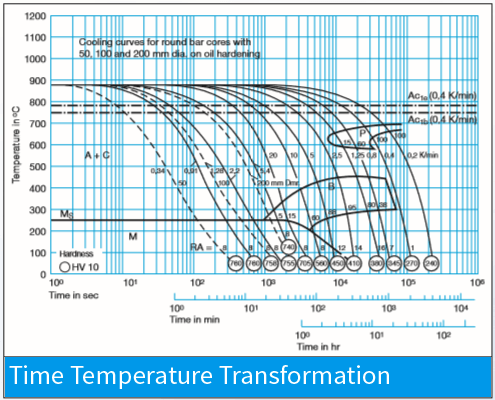

Based on the desired hardness, toughness, and other mechanical properties of the steel required for the particular application, such as shape and size, the precise heat treatment of DB6 Steel / DIN 1.2714 / AISI L6 steel parameters, including rate of heating, austenitizing temperature, cooling, soaking time, quenching media, and tempering temperature, may vary.

Preheating at 650°C, quickly raising the temperature to the hardening range of 900–950°C, and quenching in oil.

Tempering after-hardening values /MPa|400°C: 1770,

Tempering after-hardening values /MPa|500℃: 1570 ,

Tempering after-hardening values /MPa|600°C: 1320,

Tempering after-hardening values /MPa|650℃: 1180

Gradually Warm up to 700 °C, then quickly raise the temperature to 1050 °C. Keep forging over 800 °C. After forging, it is important to cool slowly, either in a furnace or in a vermiculite.

Heat the component gently to 600–650°C for stress release, and then give it a thorough soak for two hours every 25mm of section. Cool to 500°C in the boiler before circulating freely. Before hardening, tools can then be finished machining.

DB6 Steel / DIN 1.2714 / AISI L6 – Hot-Work Mold Steel should not be normalized due to its air-hardening ability .

Soak Thoroughly at 740-760 °C before furnace cooling at a maximum rate of 10 °C per hour down to 600 °C followed by cooling in air.

Cold working is needed for shaping or forming the material, it is generally recommended to perform the operations on the steel in its annealed or soft condition before the heat treatment process.

DB6 Steel / DIN 1.2714 / AISI L6 steel can be nitride to give a hard surface case, The steel is very resistant to wear and erosion .Before nitriding the tool steel should be hardened and tempered at approx 50 °C above the nitriding temperature.

Stress tempering for a pre hardened condition.

In order to produce the appropriate hardness and mechanical qualities for DB6/ DIN 1.2714 / AISI L6, quenching is a critical stage in the heat treatment process. The temperature range above the critical temperature (AC3) is required for quenching steel utilizing an oil and air medium in order to completely change the steel's microstructure into a hardened condition.

| Soft annealing °C | Cooling | Hardness HB |

|---|---|---|

| 650-710 | Furnace | max. 240 |

| Hardening °C | Quenching | Hardness after quenching HRC |

|---|---|---|

| 840-880 | Oil | 57 |

| 860-900 | Air | 55 |

| Tempering °C after quenching | 100 | 200 | 300 | 400 | 450 | 500 | 550 | 600 | 650 |

| in Oil - HRC | 56 | 54 | 52 | 49 | 47 | 46 | 43 | 38 | 34 |

| in Air - HRC | 54 | 52 | 50 | 47 | 45 | 43 | 40 | 36 | 32 |

Dies for Drop Forging Hammers & Mechanical Presses, Die Molds, Shoe Blocks, Die Holder, Cassettes, Piston Rods, Cranks, Boaster, Shearing Blades, Tools, plastic molds, bearings, chucks parts, rollers, knuckle pins ,clutch pins, shear blades spindles,forming rolls, punches, blanking and forming dies, trimmer dies, clutch parts, pawls Shafts Etc.